1. What is a Schematic Diagram?

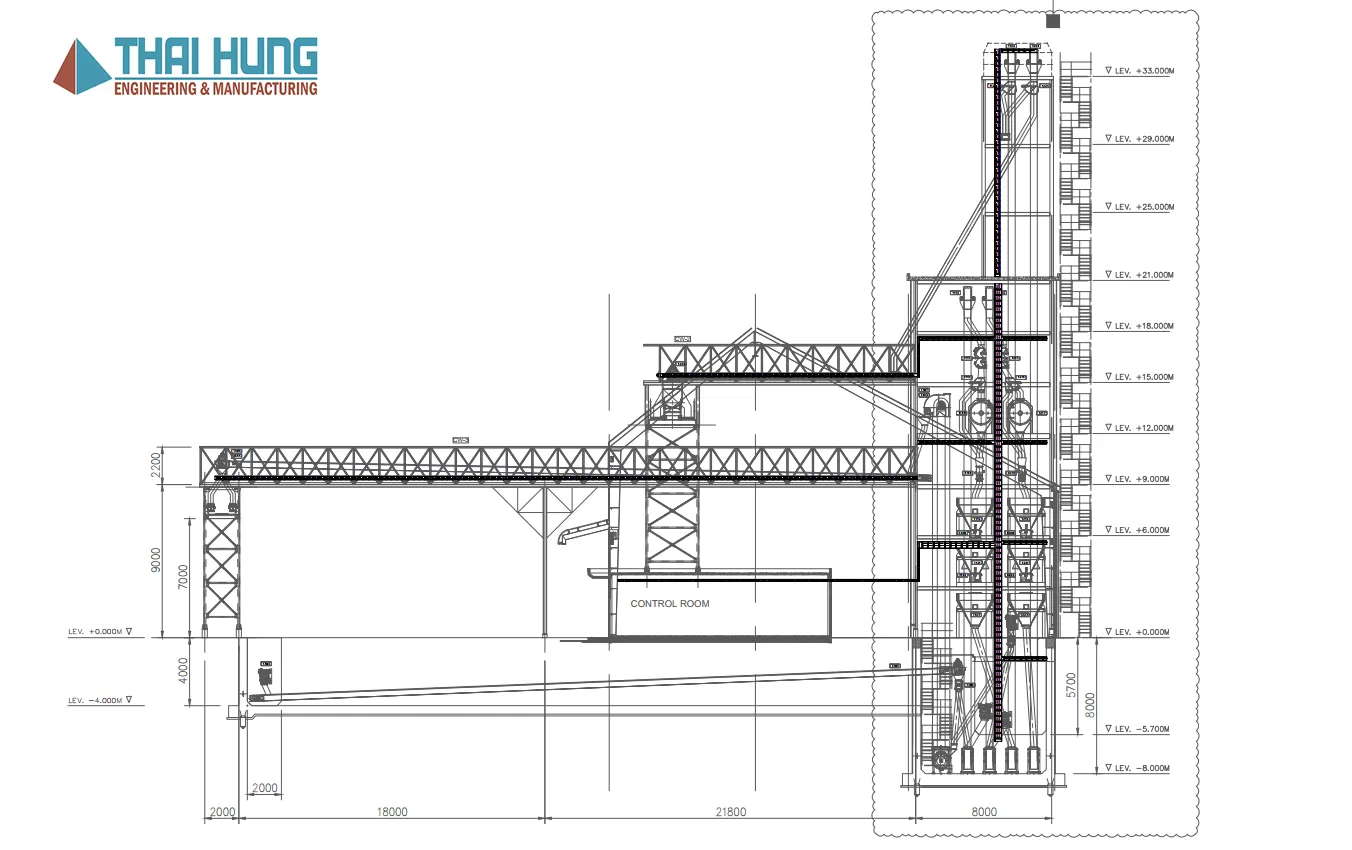

A schematic diagram illustrates the operation and interaction of equipment within a production system. In feed production plants, these diagrams typically include systems such as grinding, mixing, pelletizing, drying, and packaging.

2. The Role of Schematic Diagrams in Feed Production Plants

2.1. Ensuring Operational Efficiency

Schematic diagrams help engineers and operators understand the structure and operation of the equipment in the plant. This understanding optimizes the operational process, increasing productivity and minimizing energy waste.

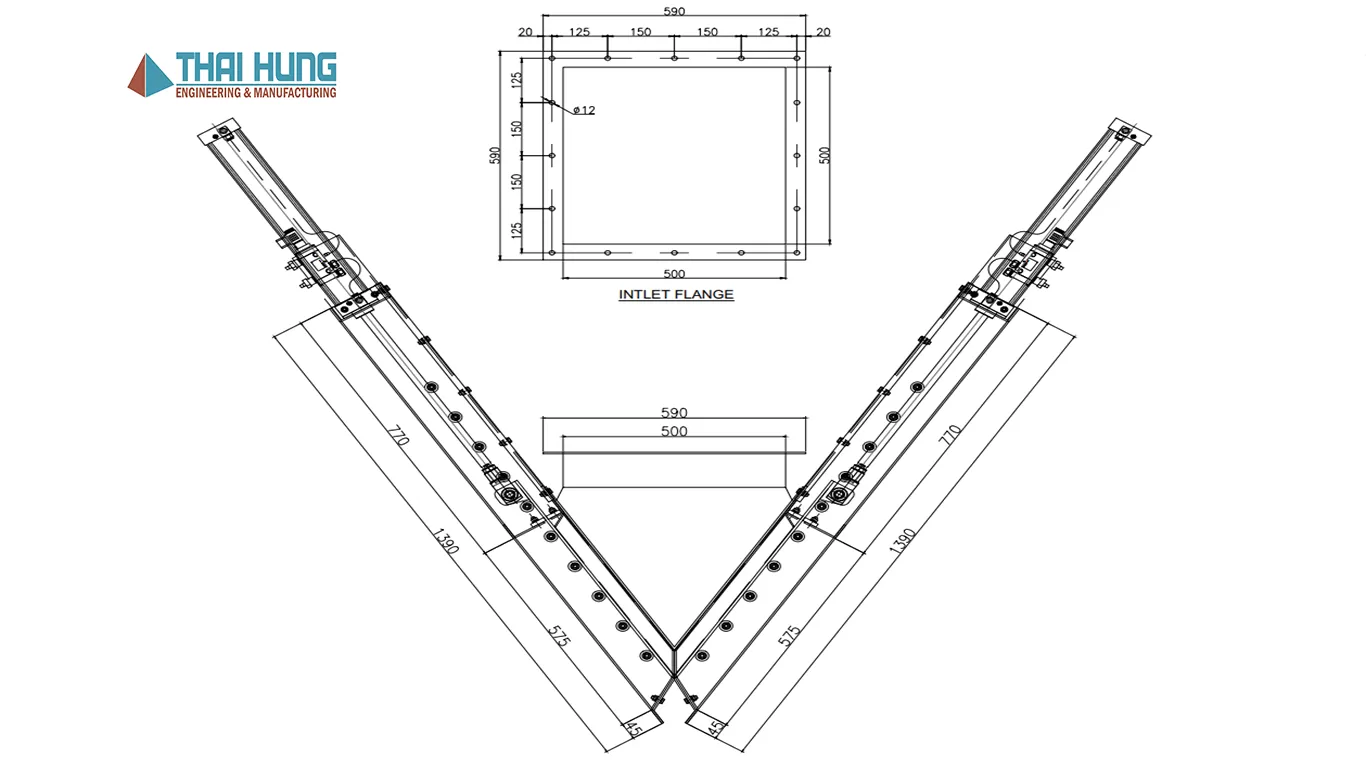

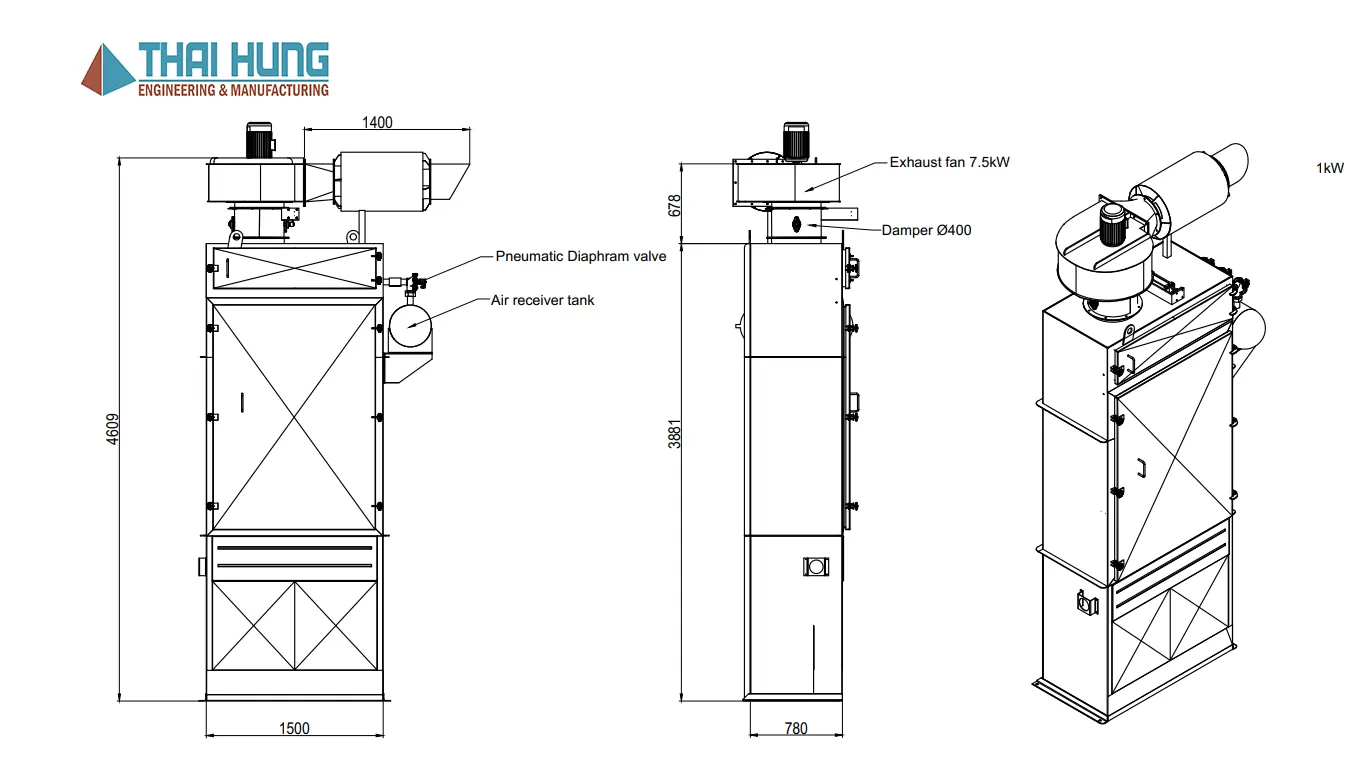

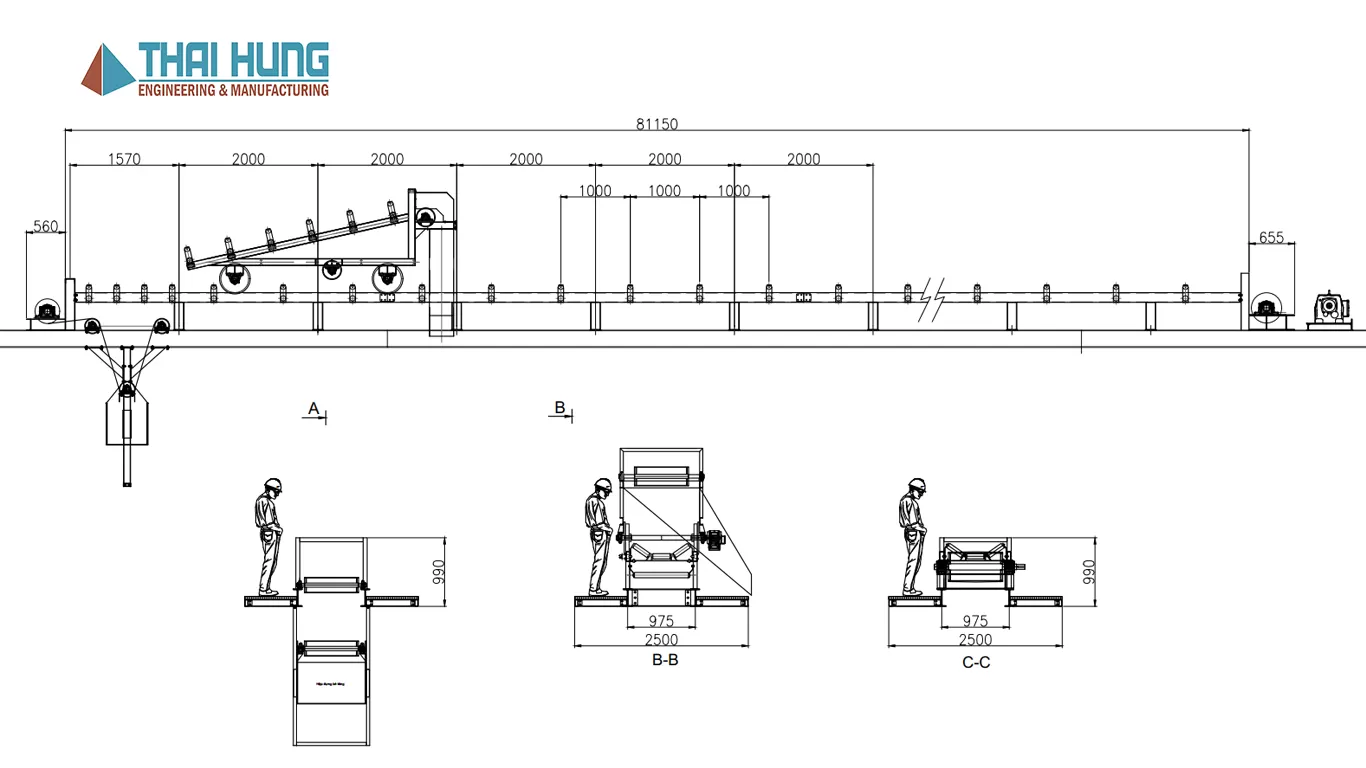

2.2. Supporting Design and Installation

Schematic diagrams serve as detailed guides for installing and connecting equipment. They help ensure proper design, reduce technical errors, and save construction time.

2.3. Ensuring Production Safety

Safety in production is a key factor. Schematic diagrams provide information on safety devices such as pressure relief valves, steam traps, and pressure control equipment, assisting in monitoring and preventing incidents.

2.4. Ease of Maintenance and Repair

When issues arise, schematic diagrams help quickly identify the location and function of each device. This saves time and costs in maintenance while increasing system reliability.

2.5. Optimizing the Production Process

Schematic diagrams allow engineers to analyze and adjust production processes to achieve optimal performance. Adjusting parameters like temperature, pressure, and time helps improve product quality, reduce energy costs, and enhance production efficiency.

2.6. Supporting Employee Training

Schematic diagrams are also useful in training new employees, allowing them to quickly grasp the process and key points in system operation.

3. Benefits of Using Standard Schematic Diagrams

- Cost Optimization in Investment and Operation: Helps select suitable equipment and optimize the production process.

- Risk Reduction: Ensures equipment operates in synchronization and adheres to technical standards.

- Enhanced Management and Monitoring: Facilitates easy tracking and evaluation of the efficiency of each process component.

4. Conclusion

Schematic diagrams are essential tools that enhance the efficiency and safety of feed production plants. Investing in detailed and accurate schematic diagrams provides long-term benefits, from production optimization to maintenance and improved product quality.

If you are looking for design and installation solutions for feed production systems, contact Thái Hưng Company for detailed consultation and professional support.