1. Ensuring Accurate Dimensions and Structure

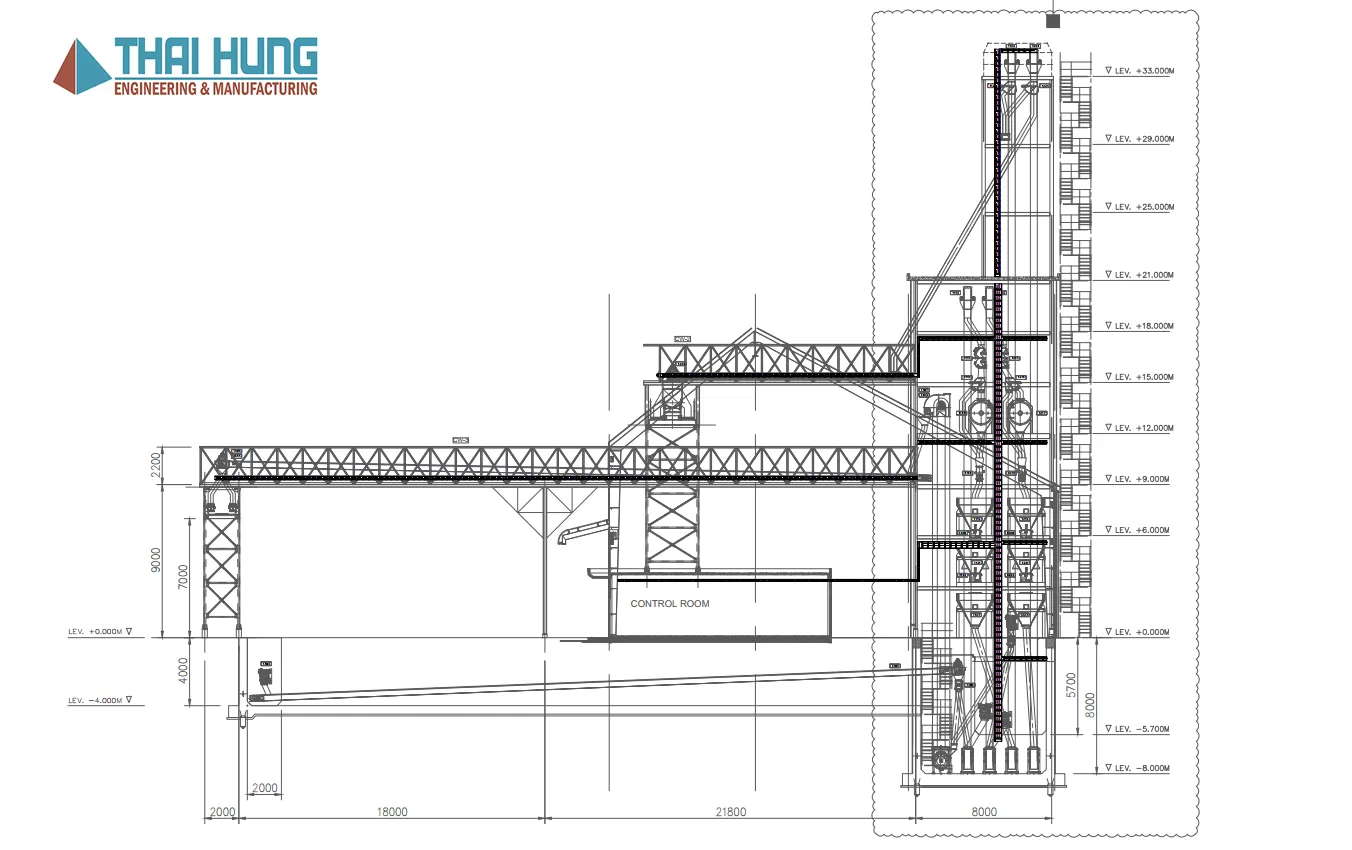

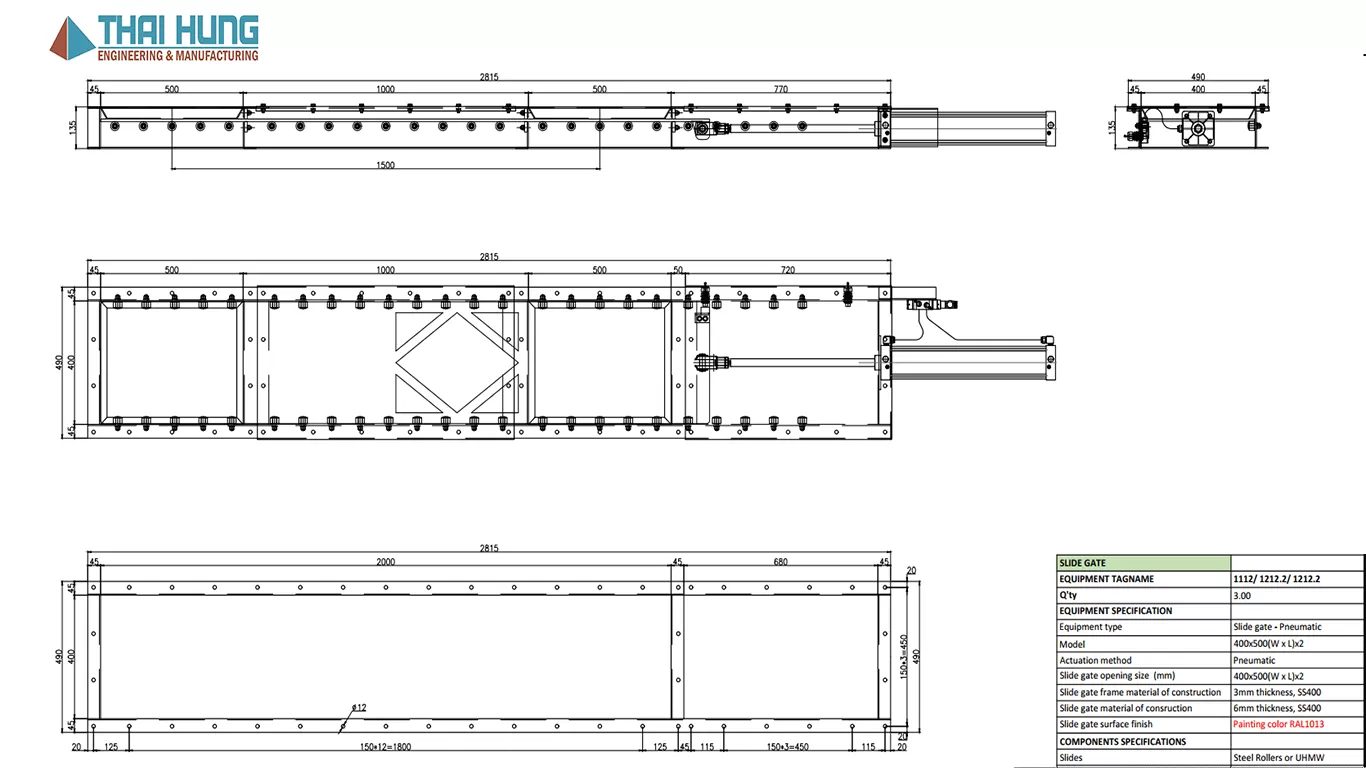

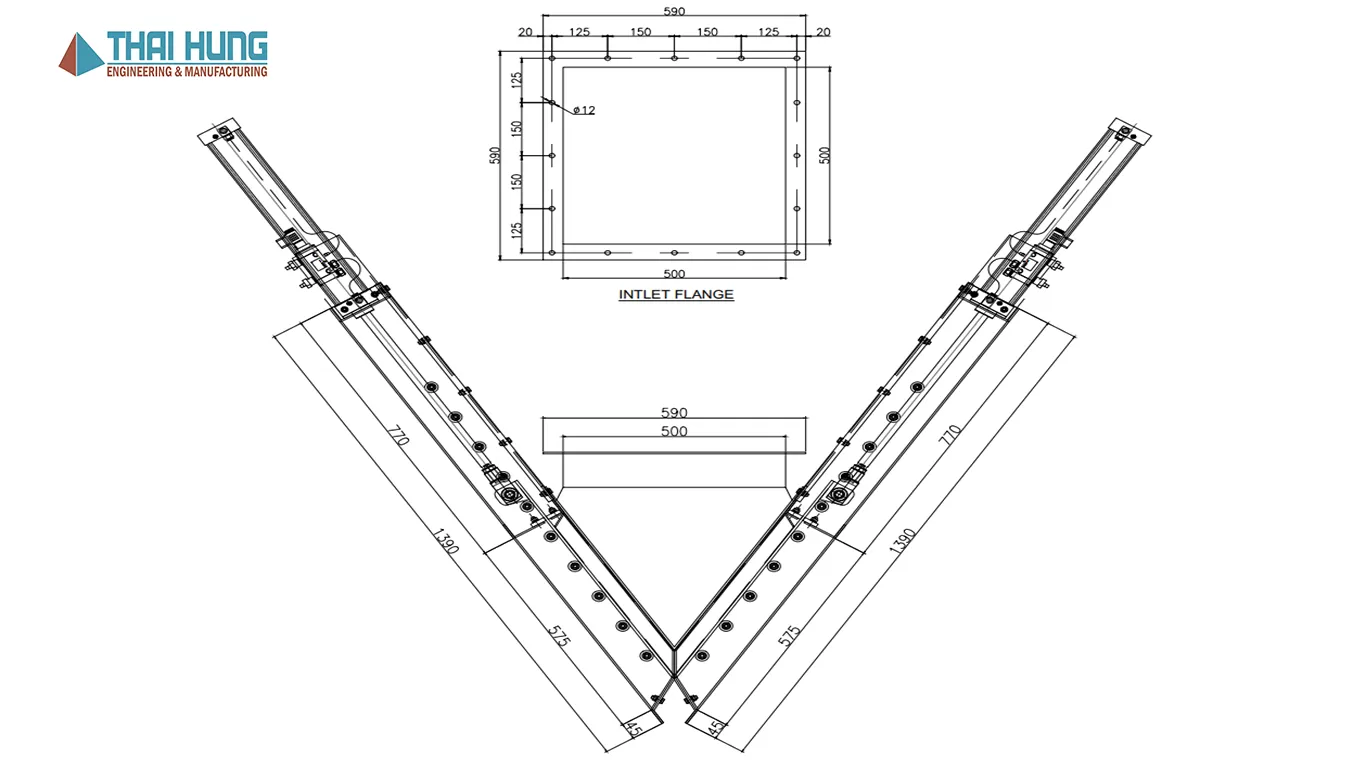

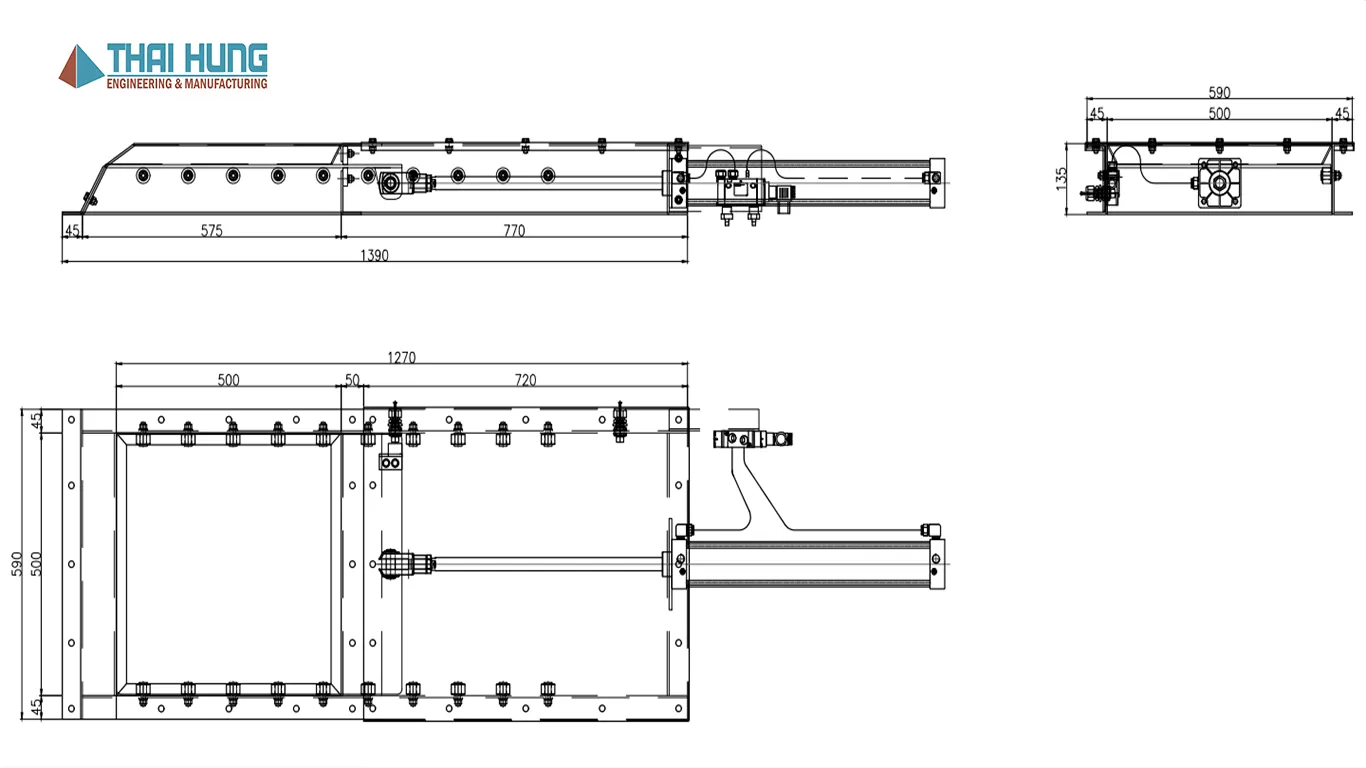

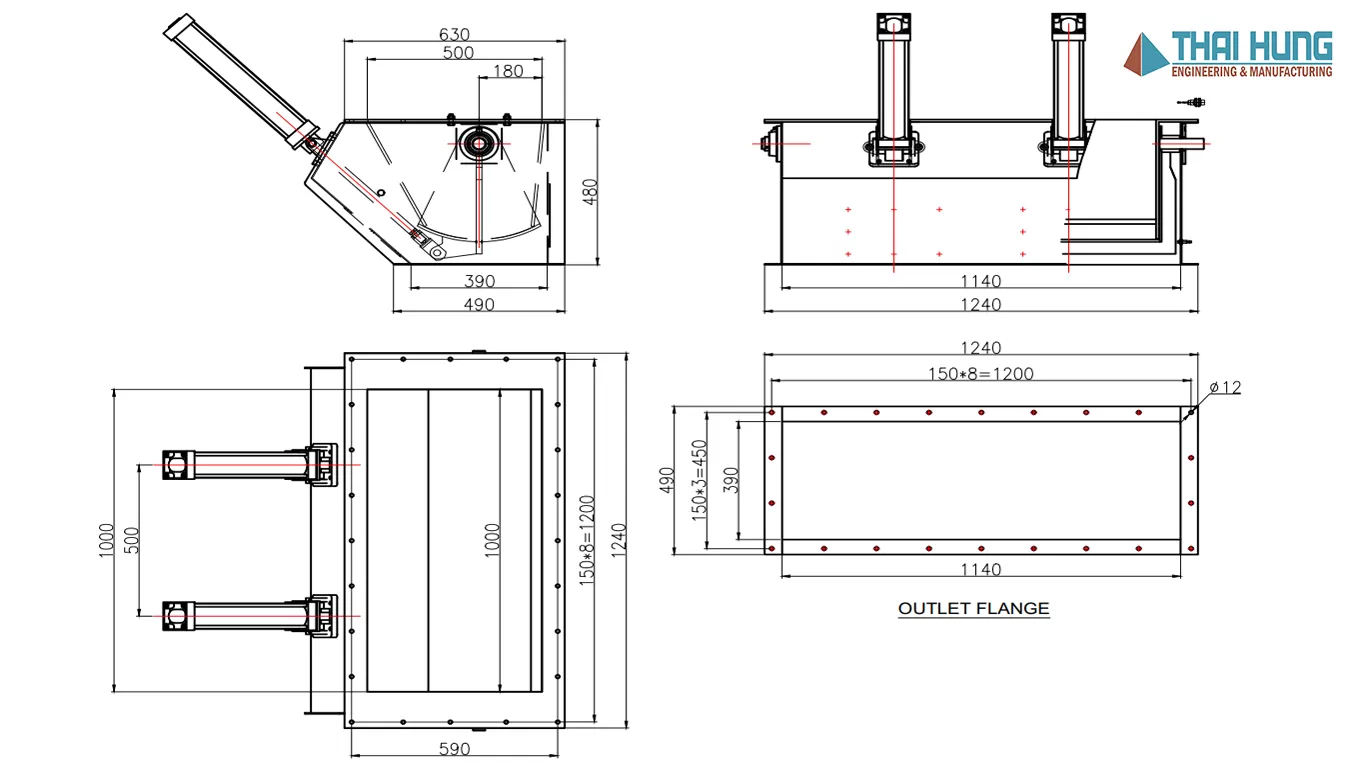

Slide Gate drawings provide detailed information about the dimensions, structure, and materials of the equipment, allowing engineers and contractors to fully understand the design before manufacturing or installation. This is essential to ensure that the Slide Gate fits the current system and operates accurately.

2. Supporting Efficient Installation and Maintenance

Slide Gate drawings help determine the precise installation location within the system, minimizing errors and saving construction time. Additionally, the drawings provide information on maintenance points, enabling technicians to easily perform routine maintenance tasks.

3. Ensuring Safety and Optimizing Performance

Having detailed drawings ensures that the equipment is manufactured and installed according to safety standards, avoiding unwanted risks during operation. Stable Slide Gate performance helps optimize the entire production line's efficiency, thereby enhancing product quality.

4. Supporting Evaluation and Improvement Processes

Slide Gate drawings also serve as a critical foundation for evaluation and improvement processes. When upgrades or equipment changes are needed, the drawings help engineers easily identify elements that need adjustment to meet the new system requirements.

Conclusion

Slide Gate drawings are not just technical documents but also valuable tools in installation, maintenance, and performance optimization of production systems. The accuracy and detail of the drawings ensure safety, cost savings, and enhanced plant operations, contributing to high economic efficiency.