1. What is a Cable Tray Layout Drawing?

A cable tray layout drawing is a technical document that details the installation of a cable tray system to manage and protect electrical and signal cables in construction projects. The cable tray system keeps cables organized, prevents short circuits and fire hazards, and facilitates maintenance and repair.

2. Key Factors in Designing a Cable Tray Layout Drawing

When designing a cable tray layout drawing, the following factors must be considered:

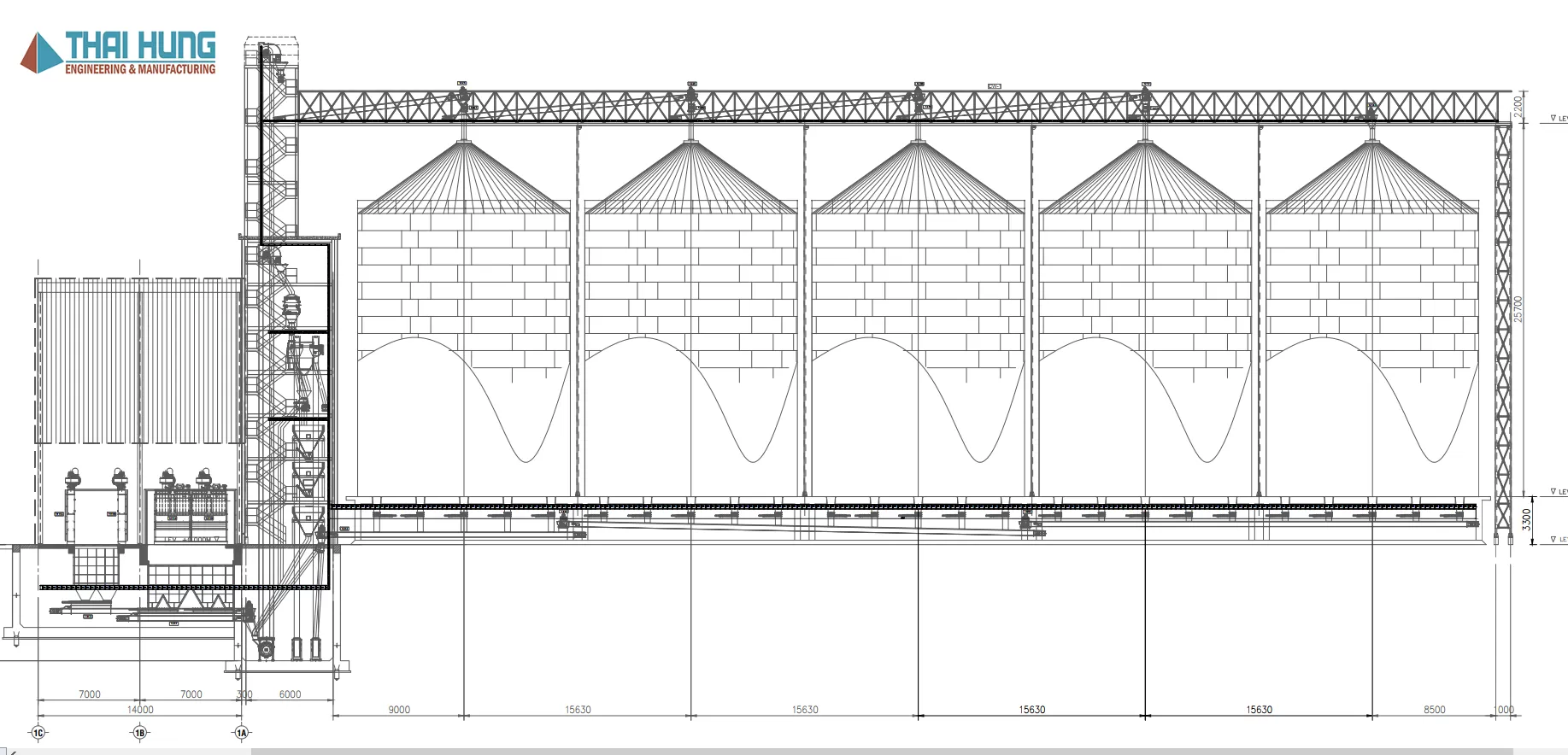

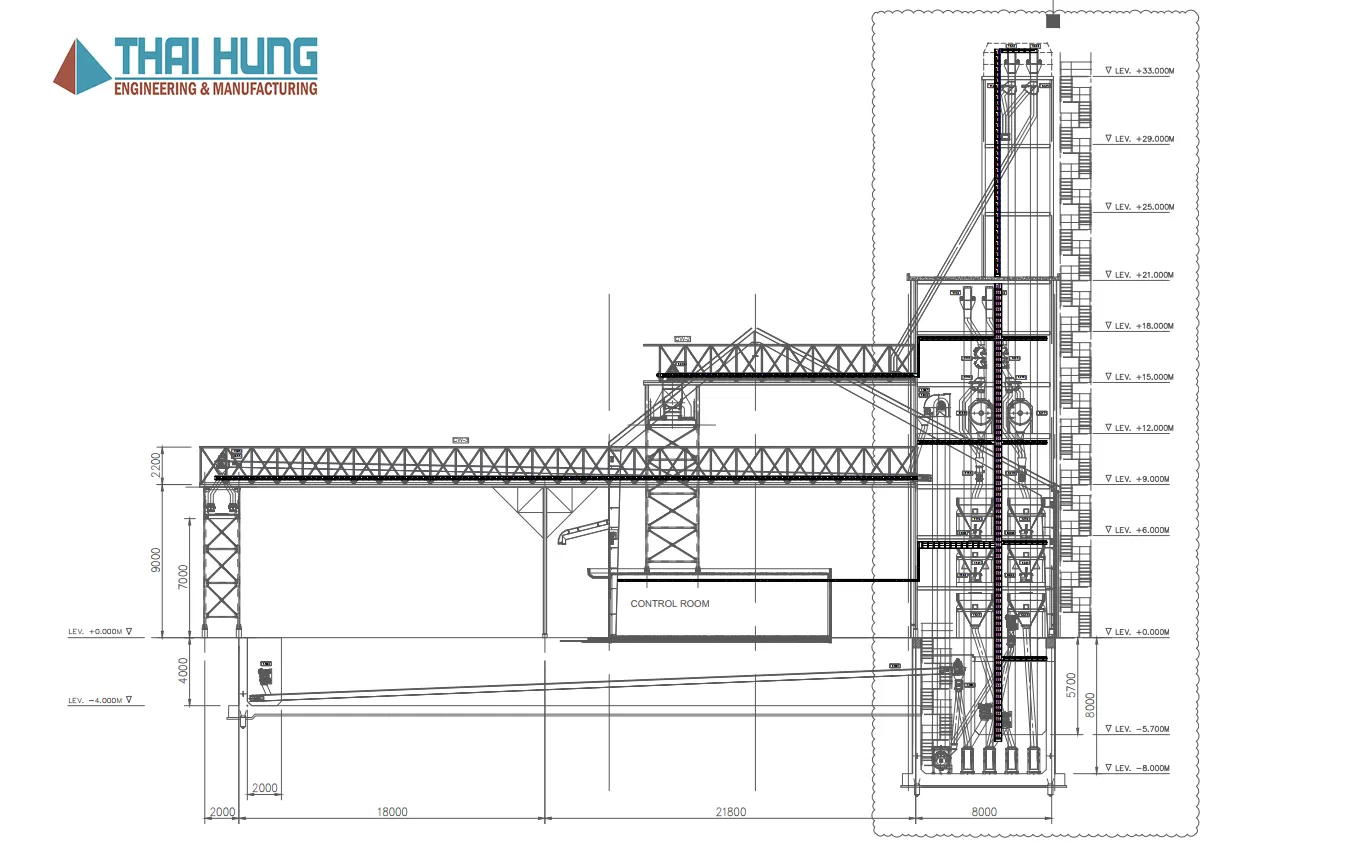

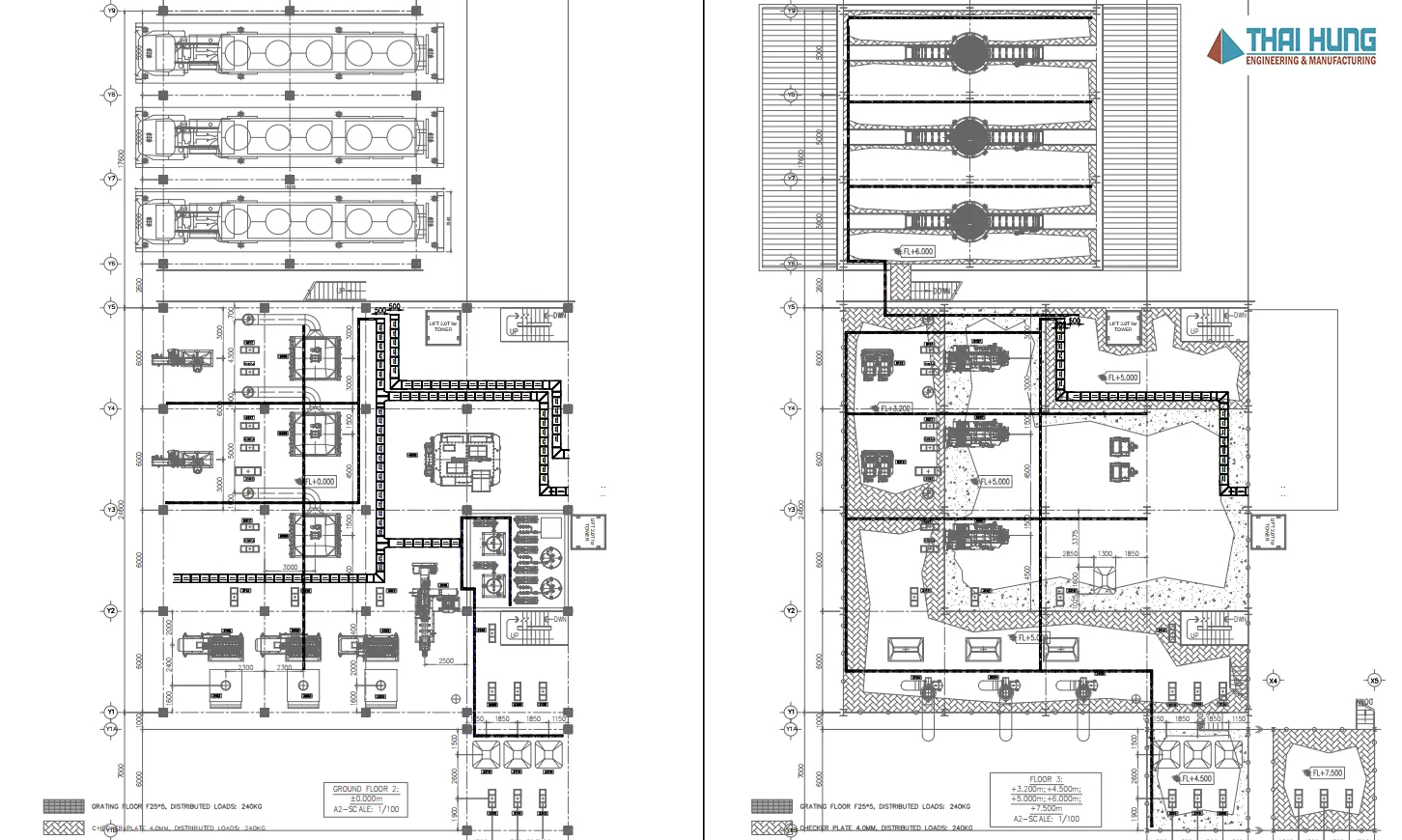

- Floor Plan: Clearly displays the position of the cable tray system within the building, helping engineers and installation teams understand the overall layout.

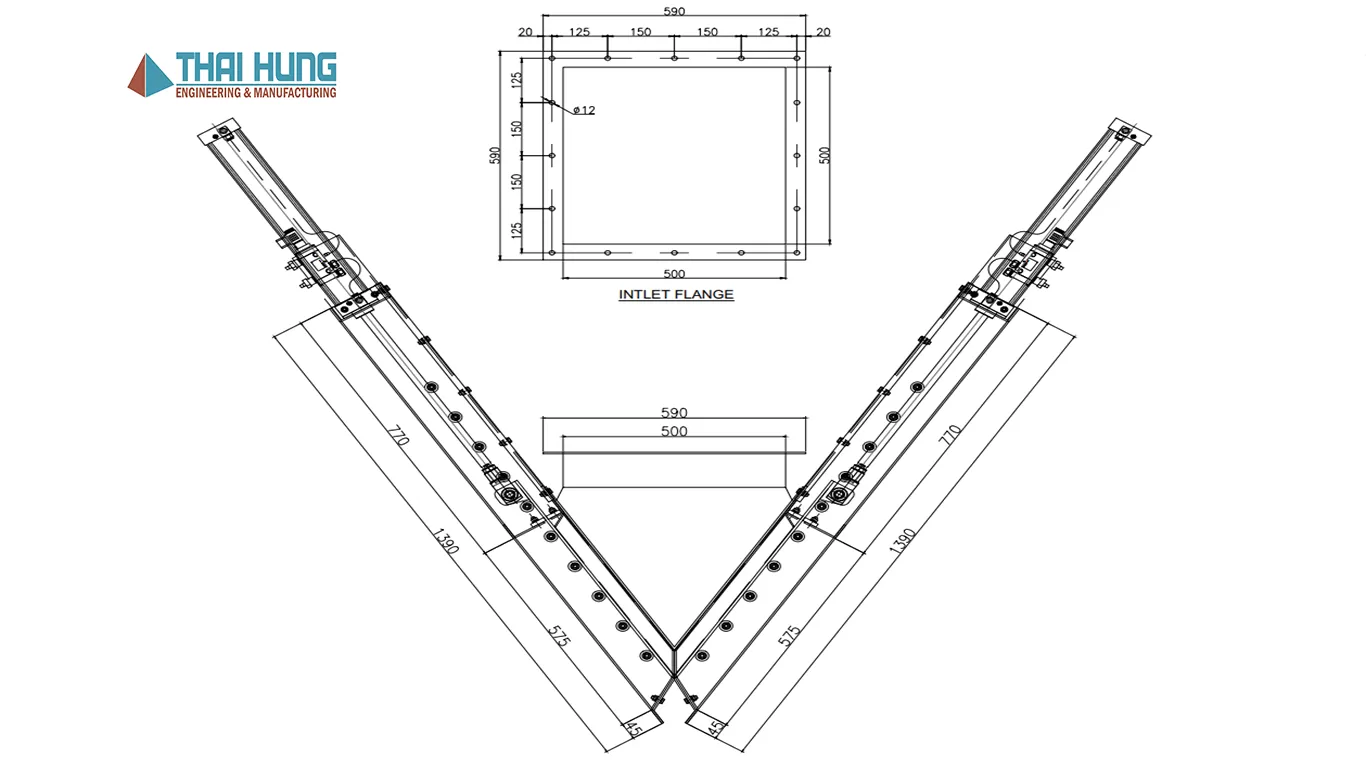

- Dimensions and Spacing: Ensure proper technical specifications, including the length, width, and height of the cable tray, and the spacing between support points.

- Type and Size of Cable Tray: Depending on the type of cable and load, select the appropriate cable tray type, such as mesh cable trays, solid-bottom cable trays, or ladder-type cable trays.

- Support and Fixing System: Design suitable brackets, struts, and fixing methods to ensure the system’s stability and safety.

3. Benefits of Using Standard Cable Tray Layout Drawings

Designing a standard cable tray layout drawing offers numerous benefits, including:

- Space and Cost Optimization: Effectively utilizes space and minimizes installation and maintenance costs.

- Safety Assurance: Reduces the risk of fire, explosion, and electrical short circuits by properly arranging and protecting cables from external factors.

- Enhanced Operational Efficiency: Facilitates the management, maintenance, and repair of the electrical system.

5. Why Choose Thái Hưng for Cable Tray System Design?

Thái Hưng, with many years of experience in designing and installing industrial electrical systems, is committed to providing high-quality services that meet the exact needs of customers.

- Professionalism and Dedication: A team of experienced engineers who prioritize quality and safety.

- Comprehensive Solutions: Offers services from consulting and design to installation and maintenance, ensuring stable and efficient system operation.

- Competitive Pricing: Optimizes costs while ensuring superior quality.

Conclusion

Designing a cable tray layout drawing is a crucial step to ensure the safe and efficient operation of electrical systems. With a professional team and extensive experience, Thái Hưng is ready to accompany you in every project.