Breakthrough in Extruder Design – Flexible and Efficient

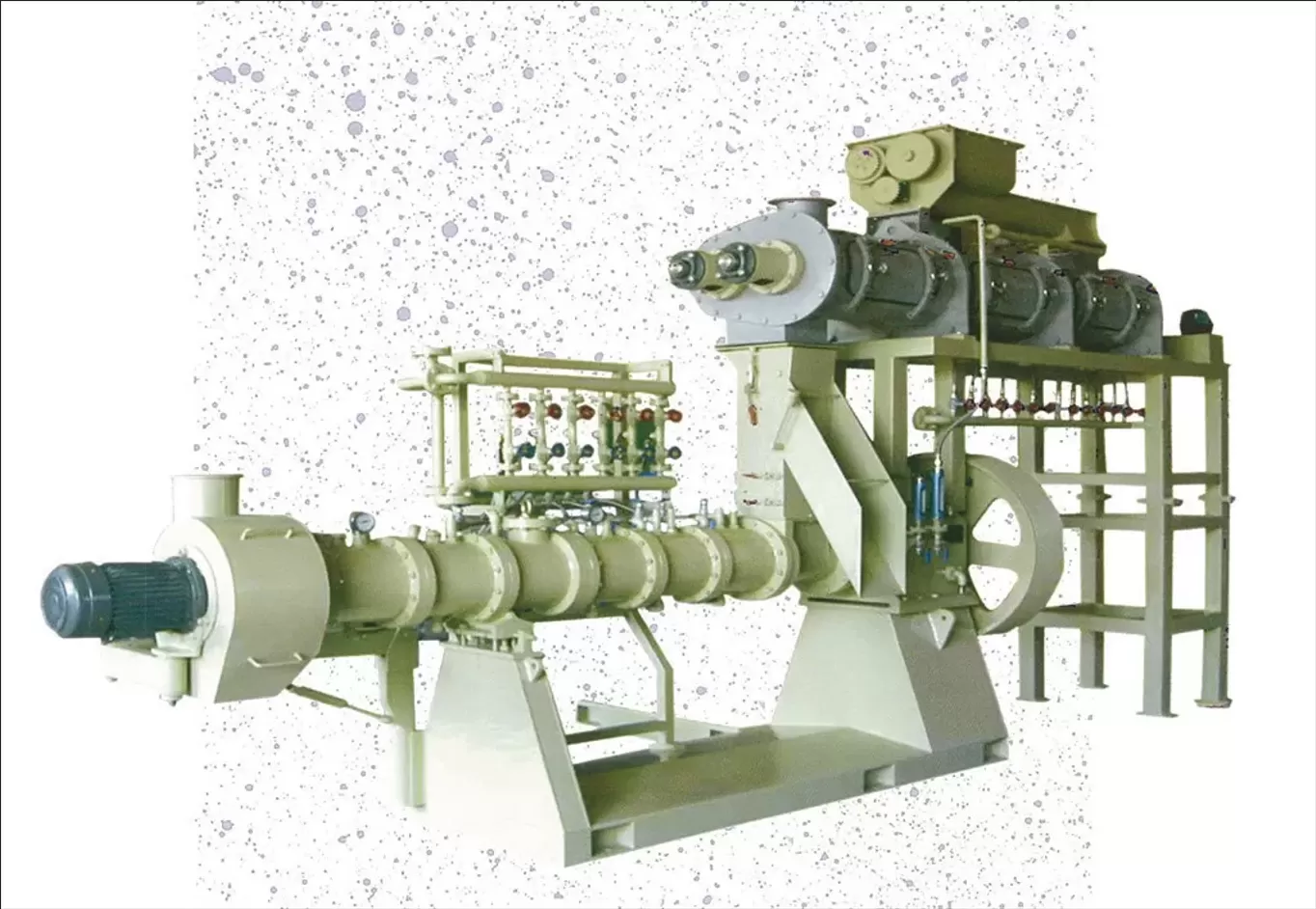

Thái Hưng continuously innovates its technology, producing a variety of extruder models, including:

-

Single-screw extruders: These are common and easy-to-use machines, suitable for extruding uniform materials. With a simple structure and low maintenance costs, Thái Hưng’s single-screw extruders increase productivity without requiring frequent adjustments.

-

Co-rotating twin-screw extruders: This machine features two parallel screws rotating in the same direction, enhancing the handling of diverse materials. It is especially suitable for materials with high viscosity or those requiring high uniformity during extrusion. This design also reduces friction, energy consumption, and improves production efficiency.

-

Counter-rotating twin-screw extruders: These extruders enhance the cutting, mixing, and dispersing of materials. They provide better control over temperature and pressure during the process.

Pre-extrusion Temperature Conditioning Technology – Ensuring Optimal Quality

A key strength of Thái Hưng extruders is the pre-extrusion temperature conditioning system. This process balances the temperature and moisture content of the materials, optimizing extrusion and minimizing wear on components such as the die and screws. Pre-extrusion temperature conditioning significantly improves the durability of pellets, ensuring consistent product quality, which is particularly important in animal feed and aquaculture feed production.

The screw design can generate uniform pressure on raw materials, creating consistent expansion and producing a crispy texture in pet food. The friction between the screw and the internal barrel lining can cook the grain materials at high temperatures in a short period.

Optimized Extrusion Dies – Enhancing Performance and Durability

At Thái Hưng, we understand that the extrusion die is crucial for shaping the product and ensuring quality. Our dies are designed with optimal compression ratios, tailored to specific materials, from animal feed to bioplastics. Moreover, all extrusion dies and screws are manufactured in-house at Thái Hưng, allowing us to customize them according to each customer’s specific requirements and ensure quick replacement when needed.

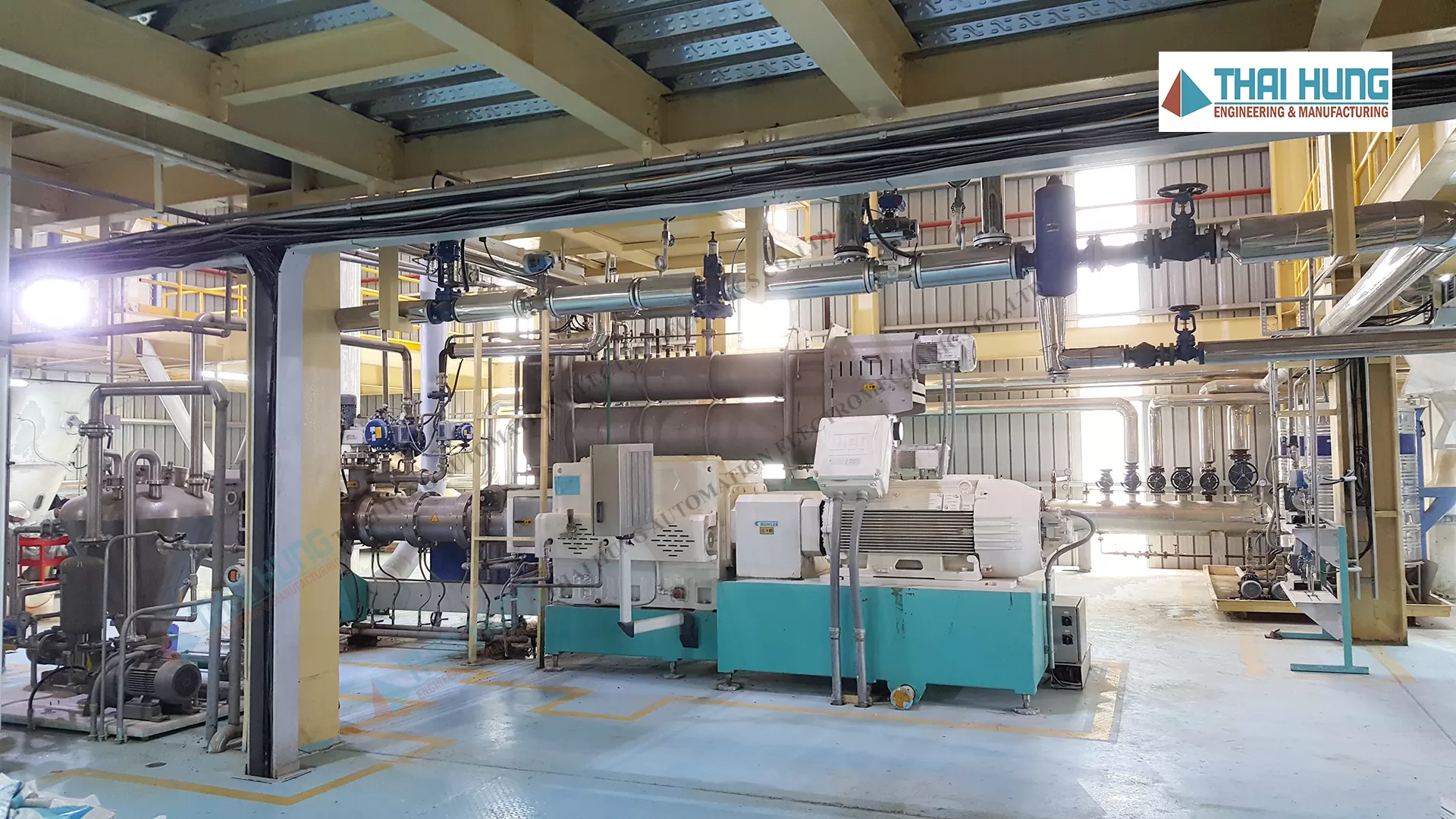

Professional Installation and Technical Support – From Design to Operation

With years of experience in the automation and mechanical industry, Thái Hưng provides comprehensive installation and maintenance services for extruders. Our team of technicians ensures the rapid and accurate installation of machines, along with providing operational and maintenance guidance to help customers operate the equipment most efficiently. Offering 24/7 customer support, Thái Hưng is committed to accompanying businesses throughout their operational journey and growth.

Customer Testimonials – Proven Reputation

Thái Hưng extruders have been used by hundreds of customers both domestically and internationally, delivering outstanding production efficiency and reducing costs. Our products have helped many businesses improve product quality, increase productivity, and achieve long-term success. Positive feedback from our customers serves as motivation for Thái Hưng to continuously innovate and improve.

Maintenance and Repair

We understand that maintenance is one of the critical aspects when choosing machinery. Thái Hưng extruders are made from high-quality metals using advanced manufacturing processes to ensure durability. The continuous lubrication mechanism for bearings and gearboxes is directly linked to the main power source as a safety measure. This lubrication system helps minimize downtime due to gearbox and bearing failures.

Our Values

The value we bring to customers helps us maintain our leading position in the food and animal feed production machinery market. In addition to marketing numerous extruders across Vietnam and Southeast Asia, Thái Hưng focuses on researching extruded food, extruded aquaculture feed, and pet food, allowing us to gain deeper insights into the technology and explore more potential products and formulas. At Thái Hưng, we study the issues our customers face during production, which drives us to continuously improve extrusion technology.