Food is one of humanity's essential needs. In the past, when the human population was low, people could rely on foraging to collect food. As the population grew, people shifted to agriculture to produce more food.

Natural food is perishable, so preservation methods are needed to reduce or prevent spoilage. Drying is one of the most effective ways to preserve food, often involving the removal of water using heat. Besides energy consumption, the drying process will alter the color, texture, smell, and other characteristics of the solid product. Therefore, it is crucial for dryers to operate efficiently with low energy consumption.

Conveyor dryers have been developed to dry food with requirements for small space, rapid product changes, lower energy consumption, lower air volume requirements, gentle tumbling on the drying surface, and even moisture distribution.

Circulate to Gently and Evenly Dry

Each Pellet is Handled with Care

PROCESS

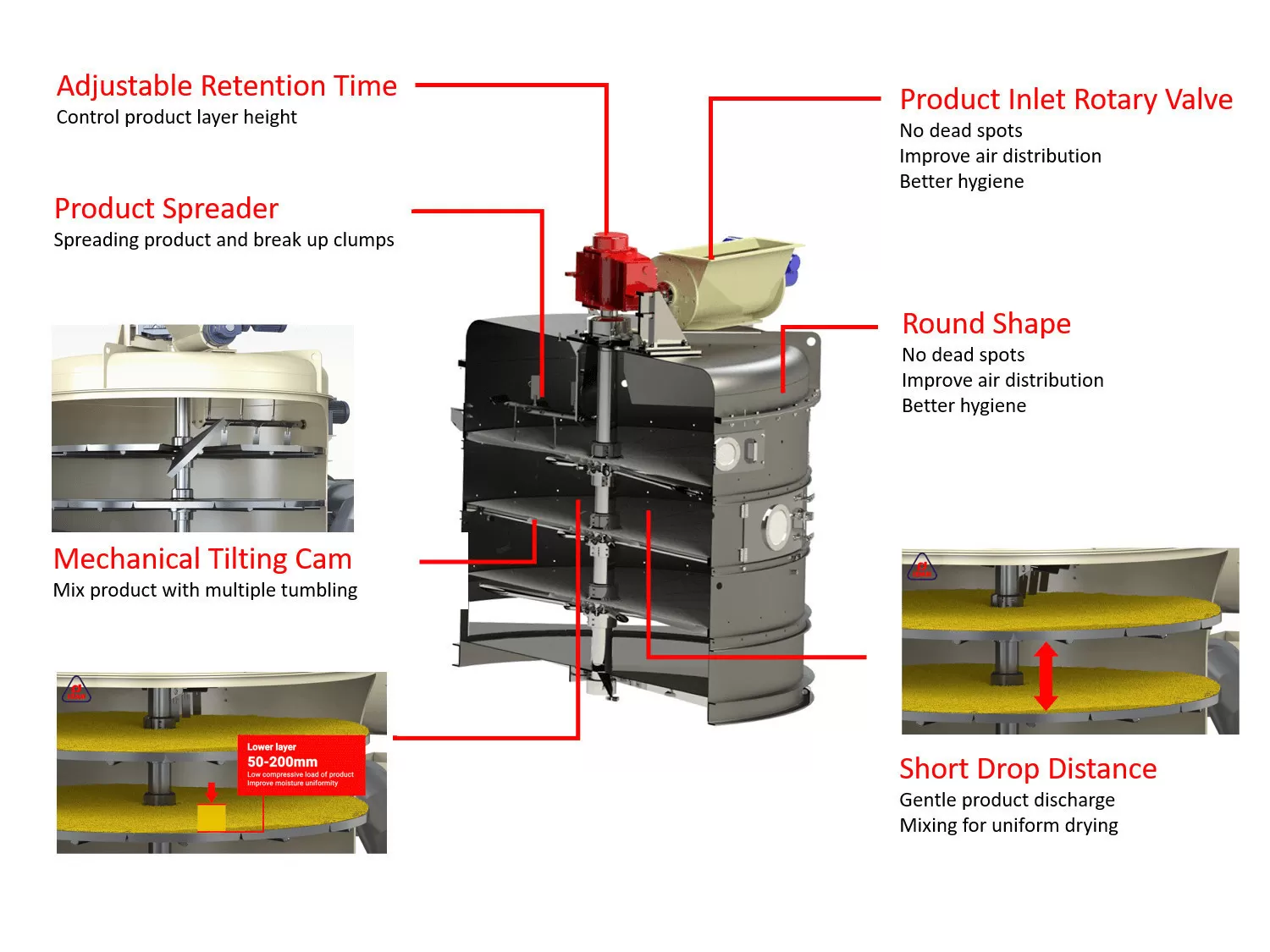

The circular conveyor dryer consists of several slowly rotating circular trays. The product to be dried is introduced from the top tray. After nearly one complete rotation, the product is discharged onto the next tray. During discharge, the product is mixed and leveled. This process is repeated until the product is discharged from the final tray into the discharge outlet.

Products can be changed without downtime, simply by emptying one tray completely.

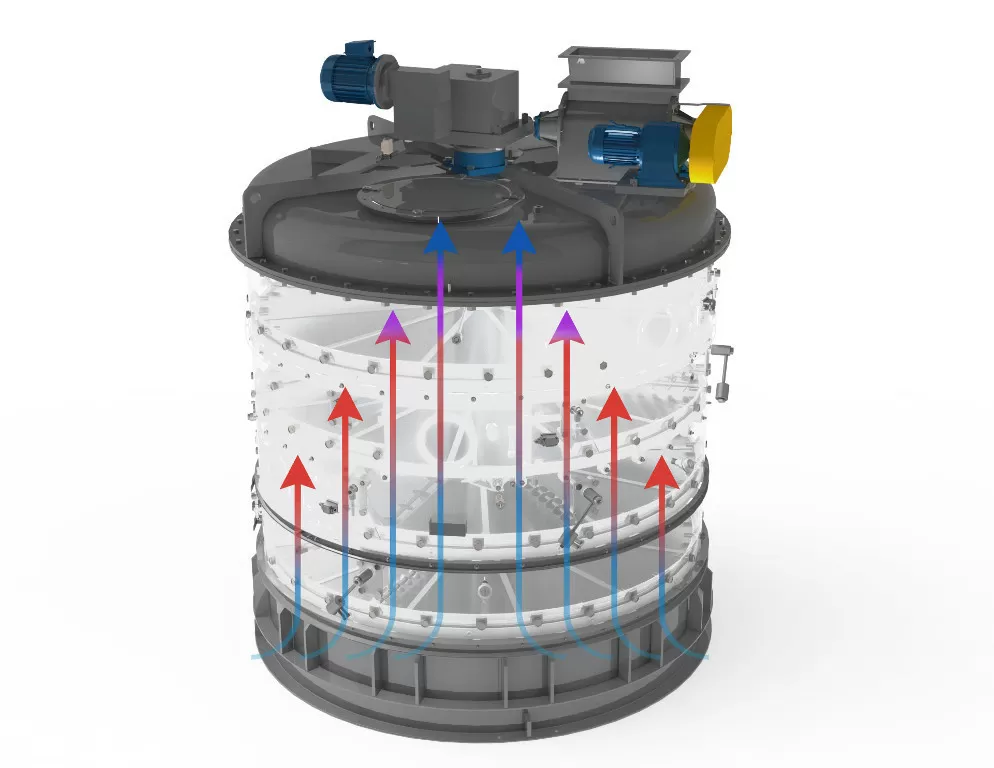

Air flows vertically through the perforated circular trays. The product moves in a circular motion within the fixed counterflow of air.

The product follows a First In, First Out (FIFO) principle. Each pellet is treated equally as it passes through different air volumes and temperatures.

The result is optimal drying uniformity.

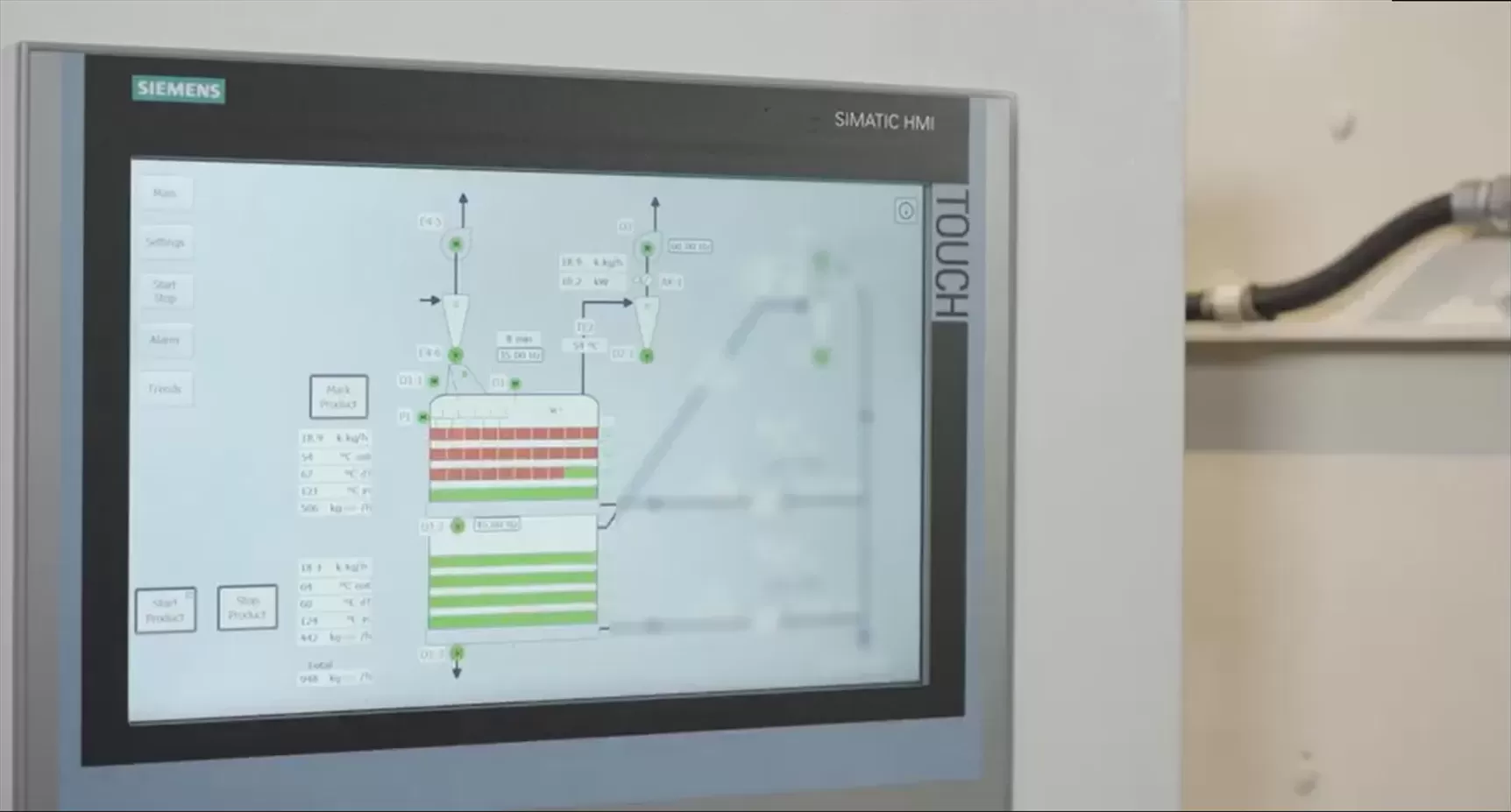

New Moisture Control System

In 2020, Thái Hưng integrated a new moisture control system. The intelligent PLC system incorporates a moisture sensor at the dryer output. This sensor will begin calibrating the dryer parameters:

-

Control of Temperature, Air Volume, and Retention Time

The drying control philosophy is a critical factor in overall performance. To achieve maximum efficiency for the uniform drying performance of the Carousel Dryer, we control energy absorption from the product by managing temperature, air volume, and retention time.

-

Water Evaporation Calculation

The system's calculation feature helps operators precisely control product moisture and monitor any changes in parameters during production. The system allows operators to achieve and maintain target moisture levels quickly and efficiently.

-

Energy Efficiency Indicator

With automatic calculation features, operators can see the efficiency of the drying process and take swift action whenever the figures are abnormal.

Certainly! Here’s the information organized into tables:

CAROUSEL DRYER (T Series)

| Product | Capacity (kg/h) | Moisture In (% wb) | Moisture Out (% wb) | Model | Location |

|---|---|---|---|---|---|

| Natural Cane Sugar | 1,500 | (Not provided) | 1 | T300.3 | Germany |

| Pistachios | 2,000 | 22 | 5 | T225.5 | Germany |

| Breadcrumbs | 1,700 | 38 | 10 | T300.2 | Netherlands |

| Cocoa Nibs | 5,100 | 30 | 11 | T300.5 | Brazil |

CAROUSEL DRYER AND COOLER (TK Series)

| Product | Capacity (kg/h) | Moisture In (% wb) | Moisture Out (% wb) | Model | Location |

|---|---|---|---|---|---|

| Whole Meal | 630 | 40 | 12 | TK300.2.1 | Germany |

| Almonds | 2,000 | 45 | 27 | TK300.3.2 | Germany |

| Corn Germ | 3,000 | 17 | 12 | TK260.4.2 | Italy |

| Coffee Beans | 5,800 | 16 | 12 | TK300.3.2 | Italy |

| Corn Grits | 2,500 | 22 | 14 | TK300.3.4 | China |

| Extruded Solids | 700 | 12 | 3 | TK200.2.1 | Switzerland |

| Wheat Grain, Honey C. | 5,000 | 20 | 10 | TK300.6.2 | France |

| Rice, Pasta | 1,200 | 13 | 8 | TC260.3.1 | Brazil |

| Flour Additives | 1,100 | 20 | 8 | TK300.3.1 | Denmark |

CAROUSEL COOLER (K Series)

| Product | Capacity (kg/h) | Temperature In (°C) | Temperature Out (°C) | Model | Location |

|---|---|---|---|---|---|

| Candy, Caramel | 800 | 80 | 25 | K260.2 | Germany |

| Extruded Grain Flour | 830 | 100 | 20 | K260.2 | Germany |

| Almonds, Apricot Kernels | 1,000 | 55 | 20 | K200.4 | Germany |

| Spices | 600 | 60 | 15 | K260.3 | Sweden |

| Flaked Grains | 1,170 | 130 | 20 | K200.3 | Netherlands |

| Breadcrumbs | 2,000 | 100 | 20 | K260.2 | United Kingdom |

| Milk Replacer Feed | 5,300 | 35 | 4 | K300.6 | Switzerland |

Uniform Moisture Dryer for Your Needs

Our team of expert engineers has worked diligently to further enhance dryer technology to increase drying process efficiency. Thái Hưng carefully considers all process requirements, uniform moisture levels, efficient energy transfer, ease of operation, and minimal downtime to select the optimal uniform moisture dryer for your industry.