Effective Mixing Solutions from Thái Hưng

Thái Hưng designs and manufactures single-paddle mixers, twin-paddle mixers, single-ribbon mixers, and twin-ribbon mixers. Each mixer line is tailored to suit specific production lines and customer demands. Among them, twin-paddle mixers and twin-ribbon mixers stand out as superior solutions, delivering the highest efficiency for feed mills, food processing plants, and other industrial applications.

The twin-shaft mixers from Thái Hưng feature more refined details and enhanced functionalities, such as pre-installed pneumatic nozzles for pipe cleaning, dual-layer stainless steel construction designed for hygienic applications in the food industry, and integrated load sensors. These mixers are available in various capacities, ranging from laboratory-scale models (20 liters) to industrial-scale models (5000 liters).

Mixing Action and Coefficient of Variation (CV)

Mixing involves kneading, rotating, and distributing to combine components with distinct characteristics and phases. Generally, there are batch mixers and continuous mixers. The double paddle mixer features two opposing shafts with multiple paddles arranged at a certain angle to distribute the material from top to bottom and from the edges to the center, ensuring thorough mixing. A fully opened discharge door guarantees that no material is left behind. The paddle design ensures fast, efficient mixing with minimal cutting for powders, pellets, granules, and particulate materials.

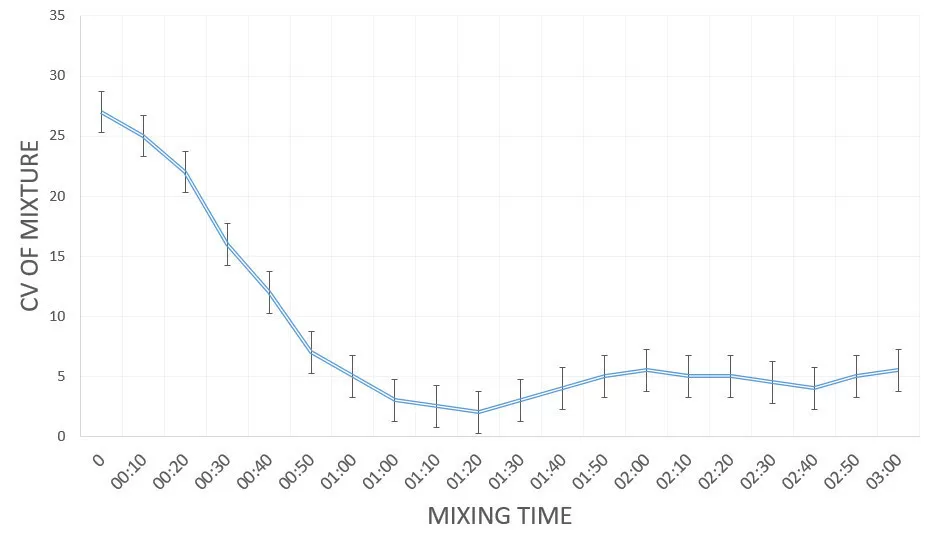

For each mixture, there is an optimal mixing time at which the material achieves the lowest CV (Coefficient of Variation). Typically, the mixing time ranges from 60 to 120 seconds. Additional mixing beyond this point may lead to segregation.

Features of the Double Paddle Mixer

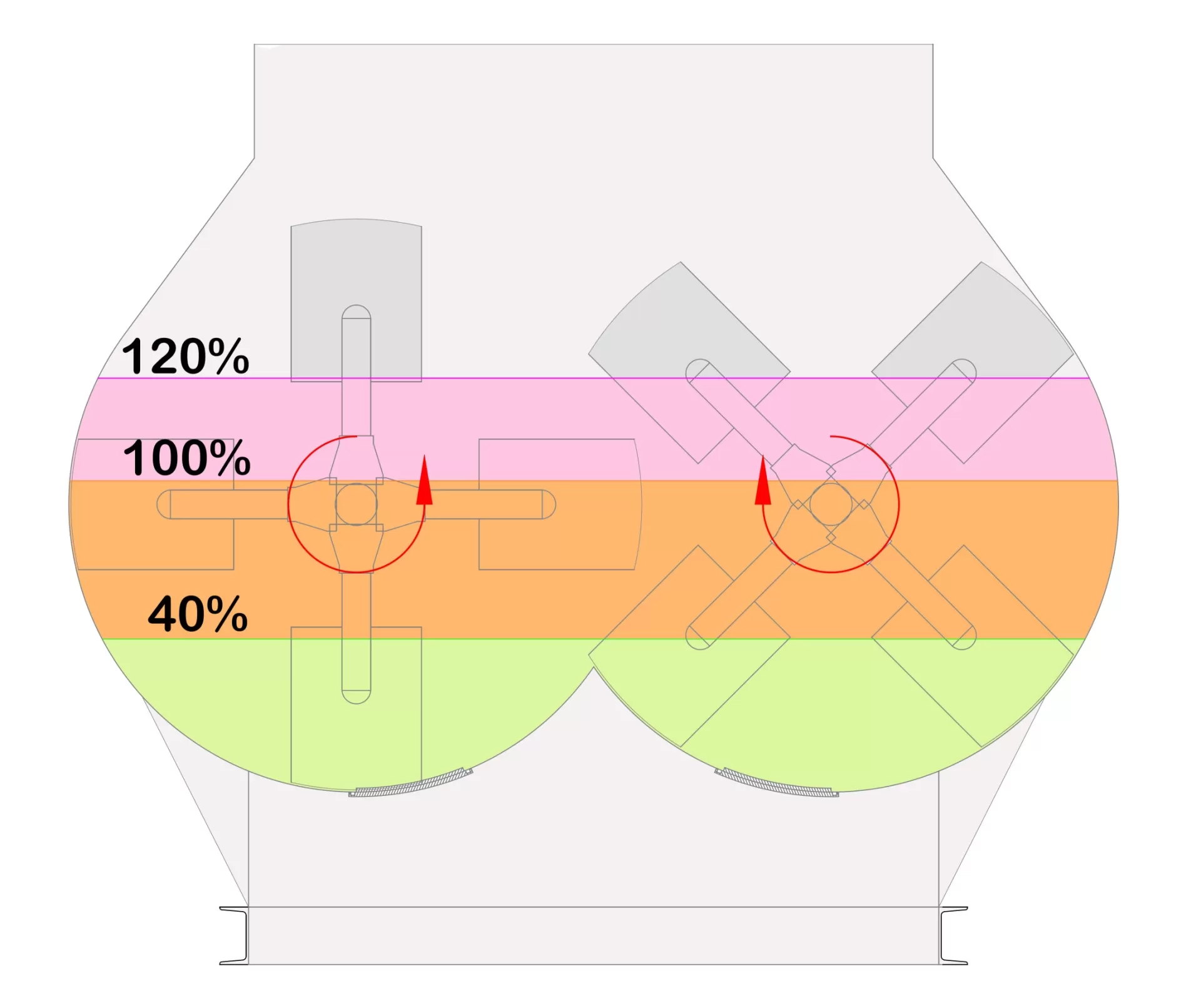

The mixing chamber of the double paddle mixer is designed in a teardrop shape. This design minimizes or eliminates material sticking to the walls. The mixer operates with flexible loading speeds ranging from 40% to 120% of its normal operating capacity. The movement of the paddles ensures that material from both sides is directed towards the center and thoroughly mixed.

Optimize Efficiency with Thái Hưng Mixers

Each mixer designed by Thái Hưng is customized to meet the specific requirements of different production lines and customer needs..

-

Single-Paddle Mixer

This model is ideal for production lines requiring moderate mixing performance. Its compact and simple design ensures ease of maintenance and operation. -

Twin-Paddle Mixer

Delivering exceptional performance, this mixer ensures high ingredient uniformity, making it particularly suitable for processes requiring precise blending accuracy. -

Single-Ribbon Mixer

The single-ribbon design optimizes mixing time, ensuring fast and even distribution of ingredients. It is best suited for powdered or granular materials. -

Twin-Ribbon Mixer

Renowned for its rapid and efficient mixing capabilities, the twin-ribbon mixer handles complex materials with ease. It is an optimal choice for modern production lines with high-capacity demands.

With customizable designs, superior product quality, and comprehensive services proven through major projects, Thái Hưng takes pride in being a trusted choice for our customers. Notably, 80-90% of our clients return to use our services, a testament to their satisfaction and confidence in us.

If you are looking for optimal mixing solutions for your production line, contact Thái Hưng today for the best consultation and support. Hotline: +84 982 097 247